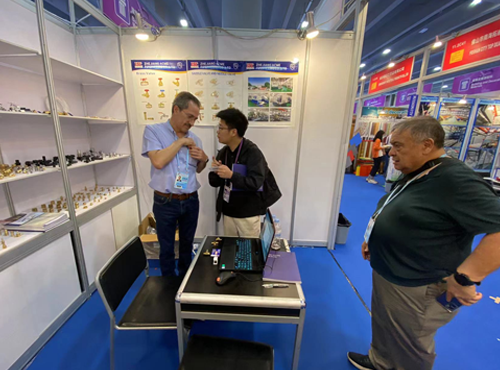

Zhejiang Acme Pipefitting Co., Ltd. achieved significant sales success at the 2024 Spring Canton Fair, signing a $50,000 contract with a U.S. client, Client A. This collaboration was made possible through our high-quality copper fittings and ball valves, further strengthening our competitiveness and influence in the international market.

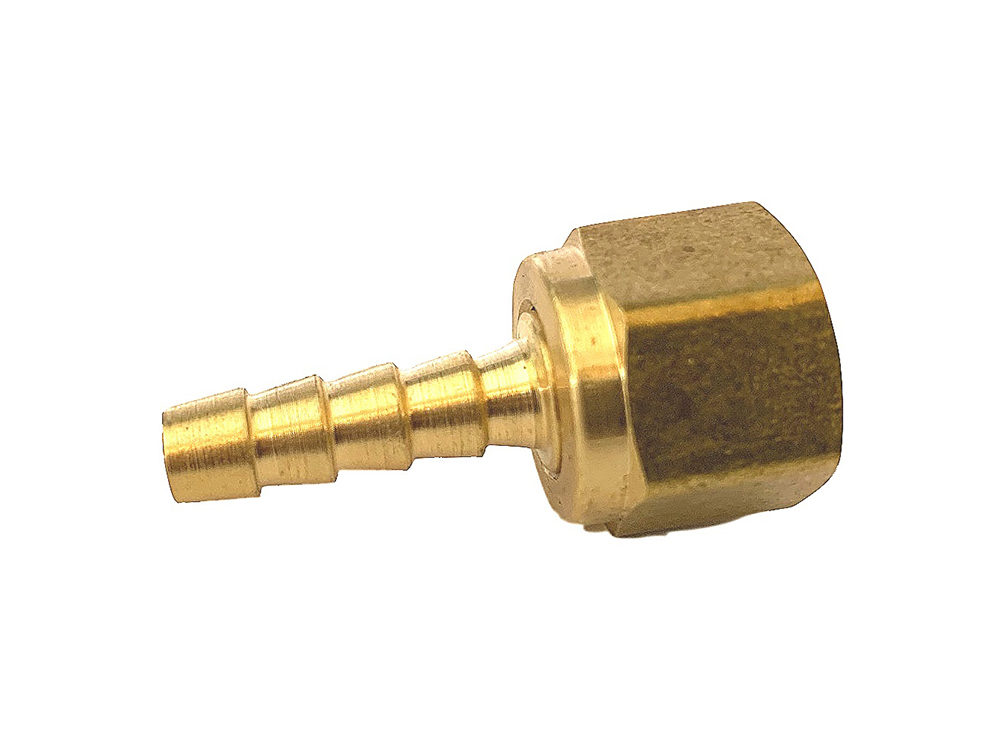

1.Extensive Product Line

2.Stringent Quality Control

3.Timely Supply

Obtained the ISO14001:2015 quality、NSF and UPC certifications.

Our product line capable of fulfilling various intricate installation requirements.

Solve problems quickly, and let customers have no worries.

Zhejiang Acme Pipefitting Co., Ltd.

Zhejiang Acme Pipefitting Co., Ltd. (formerly known as Changshan Hongfeng Pipefitting Co., Ltd., abbreviation: HT.), since its establishment in 2002, has been deeply engaged in the pipe fitting industry. With exquisite craftsmanship and excellent quality, it has become a leader in the industry.

-

Extensive Product Line

-

Professional Manufacturing and Processing

-

Stringent Quality Control

-

Customization Service

-

Surface Treatment and Heat Treatment

-

Timely Supply

2000+

Happy Clients

150+

Employee

20000+㎡

Area

+ 86 18705708777 / 86-570-5111288

Our OEM customization services can be offered based on the specific needs of customers. Providing efficient and convenient customization solutions for customers.

Contact UsVisting our company online?

Improve production technology, optimize service quality, provide customers with better and more competitive products and services

PROCESS

Our Working Process

-

1

Market Demand Analysis and Product Development

Collaborate with the sales team to capture demand, analyze market trends and customerorder patterns.Conduct product design validation to ensure the design meets customer specifications, andreview and approve product technical specifications.

-

2

Raw Material Procurement and Production Processes

Determine raw material requirements, evaluate and select suppliers to ensure the materialspurchased meet quality standards.Include processes such as melting, composition analysis, dimensional cutting, forgingannealing, and CNc precision machining to ensure quality control throughout the productionprocess.

-

3

Quality Management and Supply Chain Logistics

Execute ISO quality management standards at every stage of production, handlenon-conforming products,and implement continuous improvement.Ensure appropriate product packaging to maintain integrity during transport, coordinateshipping, and monitor logistics status.

-

4

Customer Relationship Management and Continuous lmprovement

Provide customer service support, conduct after-sales follow-up, and collect feedback todrive product improvements.Regularly evaluate operational performance, optimize business processes, and enhance.

FEATURES CASE